Bauxite rotary kiln is designed mainly for bauxite processing. Bauxite ore is a kind of mineral resources commonly existing in nature. It is widely spreaded in all over the world. Bauxite rotar kiln system mainly consists of crusher, elevator, preheater, rotary kiln, cooler and dust collector.

Application:Widely applied in national defense, automobile, refractory materials, petrochemical and other industries

Taeda® rotary kiln is divided into many models, ranging from Ø2.2×38m to Ø4×60m. It can meet demands of aluminum oxide calcining work with 150 to 700t per day. Taeda bauxite rotary kiln is featured in simple structure, convenient installation and easy operation.

Low Energy Consumption

Taeda bauxite rotary kiln consumes less energy and produce products with better quality. It holds superior market advantages in terms of price.

Simple Structure

Bauxite rotary kiln holds simple structure and reasonable design. Meanwhile, it consumes less labor force and holds stable work process.

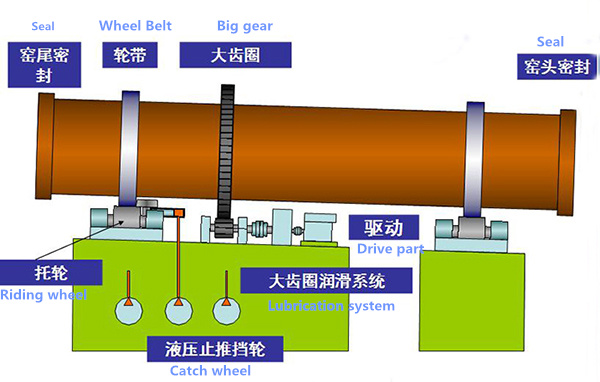

Bauxite rotary kiln structure:

Bauxite rotary kiln is mainly composed of kiln drum, transmission device, support device, catch wheel, seal device and kiln head cover.

Jinan Lime Kiln Production Line

Attracted by lime rotary kiln manufactured by Zhengzhou Taida, Jinan customer purchased a whole set of lime rotary kiln calcining machine to fulfill final production aim.

Raw material: Lime

Output capacity:350t/d

10TPH Russia Gypsum Production Site

Gypsum for is with high moisture. For guaranteeing smooth feeding, there is a certain inclination of feeding end for gypsum kiln. Whole line contains burner, rotary kiln and exhaust disposal.

Raw material:Phosphaste gypsum

Output capacity:1-10T/H

| Model | Capacity(t/d) | Support roller (Group) | Gearbox | Motor | Power(kW) |

| Ø2.2×38m | 150 | 2 | ZS125-5 | YVF2-225M-4 | 45 |

| Ø2.5×40m | 200 | 2 | ZS145-5 | YVF2-250M-4 | 55 |

| Ø2.8×43m | 230 | 2 | ZS165-6 | YVF2-280S-4 | 75 |

| Ø3.0×50m | 250 | 2 | ZS165-3 | YVF2-280M-4 | 90 |

| Ø3.2×50m | 300 | 2 | ZL130-16 | YVF2-315L2-6 | 132 |

| Ø3.6×55m | 450 | 2 | ZSY560-63 | YVF2-355M1-6 | 160 |

| Ø3.8×58m | 550 | 2 | ZSY560-63 | YVF2-355M2-6 | 185 |

| Ø4.0×60m | 700 | 2 | ZSY630-35.5 | YVF2-355M4-6 | 200 |