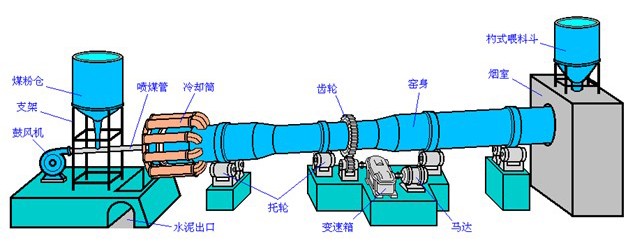

Kaolin rotary kinl is a major equipment used for kaolin calcining and production. Generally, its working temperature shall reach higher than 950℃. Kaolin rotary kiln is also called kaolin calcining kiln. Meanwhile, it can also be used for calcining both clay and kaolin materials. Kaolin rotary kiln is featured in large capacity, simple structure, less quick wear part, easy maintenance, stable performance, high running rate and good calcining quality.

Application:Final product from kaolin rotary kiln are necessary mineral materials widely applied in paper making, ceramic, rubber, chemical industry, painting and national denfense.

Application of kaolin rotary kiln is originated from the production of kaolin. Invention of kaolin rotary kiln has made the kaolin development industry develop rapidly. Soon, kaolin rotary kiln has been widely used in many industrial fields. In application field of rotary kiln, number of kaolin industry is the largest. Kaolin calcining process is a procedure which calcine kaolin and similar materials into clinker under high temperature. Therefore, kaolin rotary kiln is the main engine in the production of kaolin, commonly known as the "heart" of the kaolin factory.

1. Kaolin rotary kiln middle temperature calcining technology represents development direction of super fine kaolin calcining process featured in low energy consumption and high capacity. After dewatering, decarburization and whitening, working performance of kaolin rotary kiln is stable.

2. Taeda kaolin rotary kiln holds small grading size, high precision, large capacity, low energy consumption, low abrasion loss and high efficiency.

3. Taeda kaolin rotary kiln holds small crushing limit particle size, large crushing ratio and high processing capacity.

Jinan Lime Kiln Production Line

Attracted by lime rotary kiln manufactured by Zhengzhou Taida, Jinan customer purchased a whole set of lime rotary kiln calcining machine to fulfill final production aim.

Raw material: Lime

Output capacity:350t/d

10TPH Russia Gypsum Production Site

Gypsum for is with high moisture. For guaranteeing smooth feeding, there is a certain inclination of feeding end for gypsum kiln. Whole line contains burner, rotary kiln and exhaust disposal.

Raw material:Phosphaste gypsum

Output capacity:1-10T/H

| Model(m) | Dimension | Power(kw) | Weight(t) | ||||

| Diameter(m) | Length(m) | Slope(%) | Capacity(t/h) | Rpm(r/min) | |||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196.29 |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201.58 |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| Φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| Φ3.2×50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 |