Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

Bentonite rotary Dryer

Specifications:

Bentonite dryer or kaolin dryer is generally applied to drying granular materials, also available for drying adhesive materials, pasty materials, or materials with high moisture content.

Application Range:Industries of mining, ore beneficiation, construction materials and chemical engineering.

Applicable Materials:Slime, raw coal, flotation clean coal, mixing clean coal, slag, clay, bentonite, limestone, sand, quartz stone, metal concentrate, waste residue and tailings.

Simple structure, reliable operation

with simple structure and reliable operation, with wide application range

Enviornment friendly; no pollution emission

Flue gas produced by heat exchanger can be recycled as heating source.

With high automation level

Whole calcining process is controlled by advanced control system.

Compact structure, high cooling effciency

With reasonable structure, it can be used to cool various materials.

1. Bentonite dryer has large capacity, low fuel consumption and low drying cost.

2. Bentonite dryer has the characteristic of high temperature resistant, so it can dry material by using hot air with high temperature.

3. High scalability, the design considers the production margin, so modest increasing in output is OK without changing equipment.

4. The kaolin drying machine adopts the structure of spherical tug, and the tug and roll ring fits well, significantly reducing wear and tear and power consumption.

5. Specifically designed retaining structure greatly reduces the horizontal thrust due to tilt running of the device; Strong resistance to overload, and the cylinder of the kaolin dryer is with stable operation and high reliability.

Working Principle

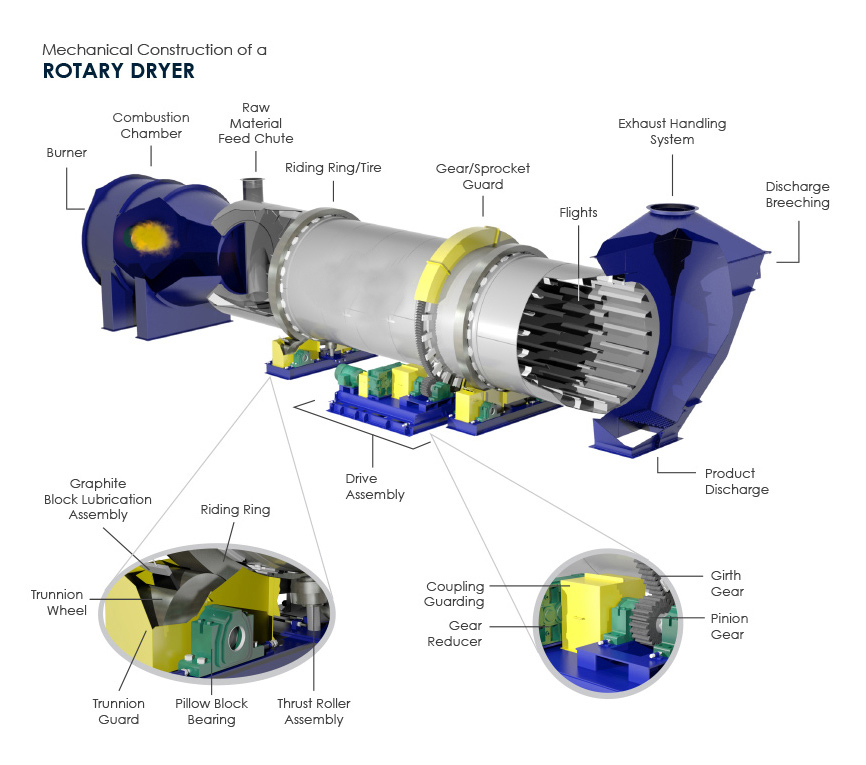

Material fed into the bentonite dryer by feeding device, then lifted to a certain height by lifting plate installed in the dryer, and will be crushed by high-speed rotating blade when items falling down, repeat the process until materials be discharged through the discharge mouth. The hot air produced by the direct combustion hot blast stove enters into the kaolin dryer and makes full contact with the material, to dry the material rapidly, and then the dried material will be discharged through the conveyor installed at the discharge end of bentonite dryer. Staggered various lifting board with different perspectives are welded inside the kaolin drying machine from front to back. In order to prevent shuffling, door ring and spiral lifting board are designed at the feed end. Kaolin dryer is installed on the roller device through the front and rear bearing device, and the blocking-wheel on the rear wheel is designed to control the axial motion of the dryer. Kaolin drying machine rotation is driven by the gearing through the rotation of fixed gears on the dryer.

Latest Delivery

Project Case

Henan 10TPH Dry Mortar Production Line

Attracted by triple-pass dryer manufactured by china famous rotary kiln manufacturer, Zhengzhou Taida, Henan construction material customer purchased a whole set of silica sand triple-pass dryer to fulfill final production aim. The picture shown above presents the real working condition of Taida lime rotary kiln.

Raw material: dry mortar

Output capacity:10T/H

20TPD Qatar Sand Production Site

Energy-saving triple-pass dryer is suitable to deal with various mineral materials such as silica, sand, ore poweder and etc. Although the moisture of sand is not high, it is difficult to reduce the inner water in it. Based on customer's real situation, we customized a whole set of sand triple-pass drying system. After arriving, we arrange professional engineer to guide installation for customer.

Raw material:sand

Output capacity:20T/D

Technical Parameters

| Model(mm) | Inclination (%) | Rotary speed(r/min) | Max inlet temperature (℃) | Power (KW) | Capacity (t/h) |

| TDMGT600 | 3—5 | 3—8 | ≤850 | 3 | Capacity will be differetn for different materials. |

| TDMGT800 | 3—5 | 3—8 | ≤850 | 4 | |

| TDMGT1000 | 3—5 | 3—8 | ≤850 | 5.5 | |

| TDMGT1200 | 3—5 | 3—8 | ≤850 | 11 | |

| TDMGT1500 | 3—5 | 3—8 | ≤850 | 15 | |

| TDMGT1800 | 3—5 | 3—8 | ≤850 | 18.5 | |

| TDMGT2000 | 3—5 | 3—8 | ≤850 | 22 | |

| TDMGT2200 | 3—5 | 3—8 | ≤850 | 30 | |

| TDMGT2400 | 3—5 | 3—5 | ≤850 | 37 | |

| TDMGT2600 | 3—5 | 3—5 | ≤850 | 40 | |

| TDMGT2800 | 3—5 | 3—5 | ≤850 | 55 | |

| TDMGT3000 | 3—5 | 3—5 | ≤850 | 75 | |

| TDMGT3200 | 3—5 | 3—5 | ≤850 | 90 | |

| TDMGT3400 | 3—5 | 3—5 | ≤850 | 110 | |

| TDMGT3600 | 3—5 | 3—5 | ≤850 | 150 | |

| TDMGT4000 | 3—5 | 1.5—5 | ≤850 | 190 | |

| TDMGT4200 | 3—5 | 1.5—5 | ≤850 | 200 | |

| TDMGT4500 | 3—5 | 1.5—5 | ≤850 | 260 |

Applicable Materials