Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

-

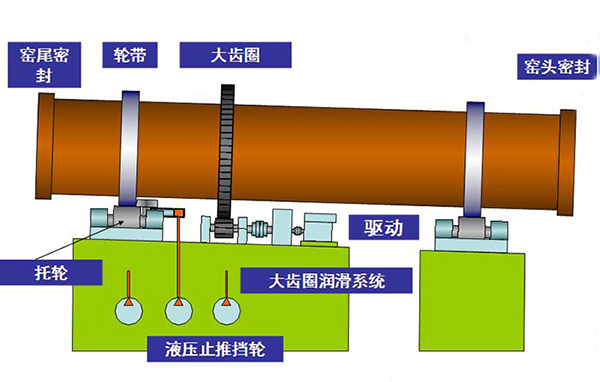

Rotary Kiln/Furnace

- Wet Type Rotary Kiln

- Dry Type Rotary Kiln

- Limonite Rotary Kiln

- Rare Earth Rotary Kiln

- Clinker Rotary Kiln

- Sludge Rotary Kiln

- Flash Boiling Calciner

- Limestone kiln Furnace

- Rotary Kiln Dryer

- Industrial Kiln Furnace

-

Drying Machine/Cooler

- Rotary Cooler

- Three-cylinder Dryer

- Limestone rotary dryer

- Quartz Sand Dryer

- Rotary Dryer

- Slag Rotary Dryer

- Coal Slime Rotary Dryer

- Bentonite rotary Dryer

- Gypsum rotary dryer

External Heating Kiln

External Heating Kiln Wet Type Rotary Kiln

Wet Type Rotary Kiln  Biomass Carbonizer

Biomass Carbonizer Limonite Rotary Kiln

Limonite Rotary Kiln