Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

Flash Boiling Calciner

Specifications:

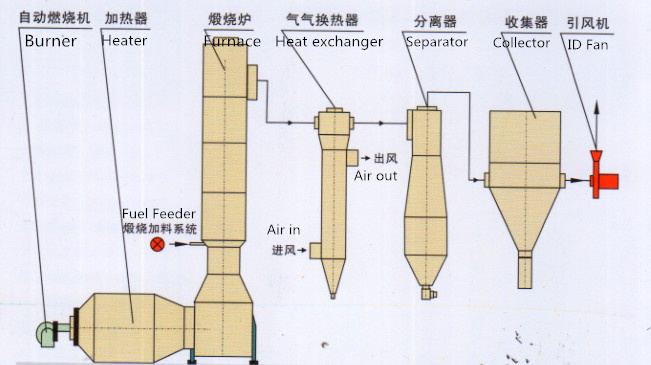

Flash boiling calciner is mainly composed of dielectric heating system, feeding system, gas-solid mixing device, calcining furnace and gas-solid separating and collecting device. Materials which need to be pre-calcined will be sent to furnace by feeding system after passing gas-solid mixer.

Application Range:widely applied to chemical, building, mining and metallurgy industry;

Applicable Materials:kaolin, boron magnesite, hemihydrate gypsum, brucite, calcium carbonate, molybdenum trioxide, fluorspar powder, magnesite and so on. Metallurgy: refining of heavy metal;

Continuous operation, instant calcination, monitoring with multi-temperature and multi-pressure points. The whole system can be controlled automatically.

Gas and solid can be mixed fully; calcining temperature and calcining period can be controlled. Finished products with stable quality;

Closed system, no pollution; adopt multi-level recycling; high recycling rate; civilized production process;

Cooler and dryer can be equipped for calcining tail gas in order to utilize heat energy effectively;

Basic configuration

The system always adopts air-inducing device; the system presents a negative pressure state; get thermal medium by indirect and direct way; adopt cooler, cyclone separator, bag filter for calcining tail gas in order to purify air and recycle products.

Special Process Configuration

In order to realize special technological aims while dealing with materials which should be processed by special technologies such as extending constant temperature period, recycling combustion air and protecting inert gas, we can offer customers with corresponding configurations and structure.

Performance of calciner

The temperature of thermal medium in calcining furnace is 300 to 1600 degrees;

<Granularity of combusted materials>60 meshes;

Fuel: solid (coal), liquid (diesel and heavy oil), gas (coal gas and natural gas);

Combustion mode: indirect, direct and multi-level mode;

Application Cases

Widely applied to chemical, building and mining industry; typical examples are presented following;

Chemical industry: magnesium, zinc, iron, lithium, inlay, aluminum, cobalt and other hydroxides, rare earth chloride, barite, cryolite, vanadium pentoxide, manganese sulfate, soda ash and so on.

Building material industry: kaolin, boron magnesite, hemihydrate gypsum, brucite, calcium carbonate, molybdenum trioxide, fluorspar powder, magnesite and so on.

Metallurgy: refining of heavy metal;

Working Principle

Latest Delivery

Project Case

Jinan 350TPD Lime Kiln Production Line

Attracted by lime rotary kiln manufactured by china famous rotary kiln supplier, Zhengzhou Taida, Jinan customer purchased a whole set of lime rotary kiln calcining machine to fulfill final production aim. The picture shown above presents the real working condition of Taida lime rotary kiln.

Raw material: Lime

Output capacity:350T/D

10TPH Russia Gypsum Production Site

Gypsum with high moisture is sent to hopper. Then, gypsum will enter the feeding end of rotary kiln dryer. Under this situation, the inclination of feeding end will be larger than natural inclination of gypsum.then, gypsum will enter rotary kiln dryer smoothly. calcining rotary kiln is a rotary drum with certain inclination.

Raw material:Phosphaste gypsum

Output capacity:1-10T/H

Technical Parameters

|

Specifications (m) |

Dimension | Power (kw) | Total weight (t) | Notes | ||||

| Diameter (m) | Length (m) | Inclination (%) | Output (t/h) | Rotary speed (r/min) | ||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | With vertical preheater |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ---- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196.29 | ---- |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ---- |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201.58 | Decomposition outside the kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ---- |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | Decomposition outside the kiln |

| Φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 | Bauxite calcining kiln |

| Φ3.2×50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | Decomposition outside the kiln |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | preheat decomposition |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | preheat decomposition |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Residual heat power |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | preheat decomposition |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | preheat decomposition |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 | preheat decomposition |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | preheat decomposition |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | preheat decomposition |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | preheat decomposition |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | preheat decomposition |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | preheat decomposition |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | preheat decomposition |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | preheat decomposition |

Core Equipment

Applicable Materials