Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

Quartz Sand Dryer

Specifications:

Sand dryer is a machine that is able to process large quantities of materials. Sand dryer is generally suitable for drying granular materials and has good drying effect especially when drying sand, river sand and quartz sand.

Application Range:widely applie to construction material,chemical industry, casting indusry, mining and metallurgy industries.

Applicable Materials:silica sand, ore slag, clay, iron powder, ore powder, cement, gypsum, coal ash and etc.

Low energy consumption

Our rotary dryer adopts reasonble running parameter; coal and electricity consumption can be 20% to 30% lower than common dryer.

High output capacity

Output capacity can be increased by more than 20%. Taida rotary kiln has been widely applied to mining and metallurgy industry.

With high automation level

The whole production line needs only one person to supervise. finished products can be directly packed and stored.

More durable

Service life can last for 8 to 10 years. with good maintenance, it can be used for longer time.

With less quick-wear parts.

Important parts adopt advanced thermal processing technology. Replace period can reach 5000 hours.

More environment friendly

Adopts multi-class dust collecting method, clean exhaust gas emission can totally meet national standard.

Working Principle

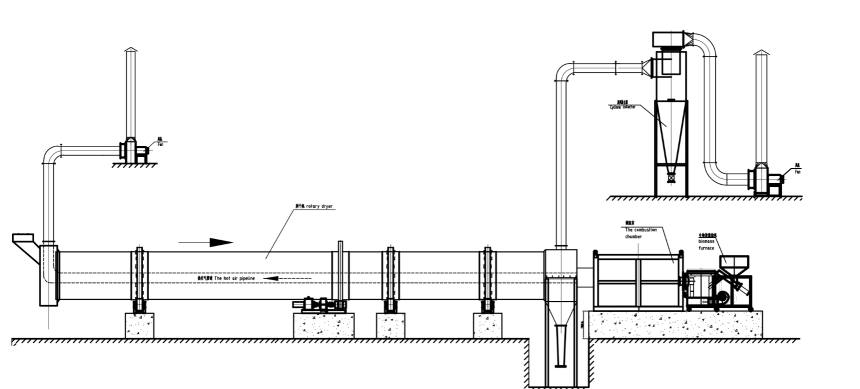

Material to be dried enters the rotary dryer and as the rotary dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the rotary dryer, when the material gets high enough to roll back off the fins, it falls back down to the bottom of the rotary dryer, passing through the hot gas stream as it fallsThis gas stream can either be moving toward the discharge end from the feed end (known as co-current flow) or toward the feed end from the discharge end (known as counter-current flow)The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the rotary dryer is called a direct heated rotary dryer, alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated, when the gas stream is preheated by some means where burner combustion gases do not enter the rotary dryer, the rotary dryer known as an indirect-heated type, often, indirect heated rotary dryers are used when product contamination is concern.

Latest Delivery

Project Case

Henan 10TPH Dry Mortar Production Line

Attracted by triple-pass dryer manufactured by china famous rotary kiln manufacturer, Zhengzhou Taida, Henan construction material customer purchased a whole set of silica sand triple-pass dryer to fulfill final production aim. The picture shown above presents the real working condition of Taida lime rotary kiln.

Raw material: dry mortar

Output capacity:10T/H

20TPD Qatar Sand Production Site

Energy-saving triple-pass dryer is suitable to deal with various mineral materials such as silica, sand, ore poweder and etc. Although the moisture of sand is not high, it is difficult to reduce the inner water in it. Based on customer's real situation, we customized a whole set of sand triple-pass drying system. After arriving, we arrange professional engineer to guide installation for customer.

Raw material:sand

Output capacity:20T/D

Technical Parameters

| Model(mm) | Inclination (%) | Rotary speed(r/min) | Max inlet temperature (℃) | Power (KW) | Capacity (t/h) |

| TDMGT600 | 3—5 | 3—8 | ≤850 | 3 | Capacity will be differetn for different materials. |

| TDMGT800 | 3—5 | 3—8 | ≤850 | 4 | |

| TDMGT1000 | 3—5 | 3—8 | ≤850 | 5.5 | |

| TDMGT1200 | 3—5 | 3—8 | ≤850 | 11 | |

| TDMGT1500 | 3—5 | 3—8 | ≤850 | 15 | |

| TDMGT1800 | 3—5 | 3—8 | ≤850 | 18.5 | |

| TDMGT2000 | 3—5 | 3—8 | ≤850 | 22 | |

| TDMGT2200 | 3—5 | 3—8 | ≤850 | 30 | |

| TDMGT2400 | 3—5 | 3—5 | ≤850 | 37 | |

| TDMGT2600 | 3—5 | 3—5 | ≤850 | 40 | |

| TDMGT2800 | 3—5 | 3—5 | ≤850 | 55 | |

| TDMGT3000 | 3—5 | 3—5 | ≤850 | 75 | |

| TDMGT3200 | 3—5 | 3—5 | ≤850 | 90 | |

| TDMGT3400 | 3—5 | 3—5 | ≤850 | 110 | |

| TDMGT3600 | 3—5 | 3—5 | ≤850 | 150 | |

| TDMGT4000 | 3—5 | 1.5—5 | ≤850 | 190 | |

| TDMGT4200 | 3—5 | 1.5—5 | ≤850 | 200 | |

| TDMGT4500 | 3—5 | 1.5—5 | ≤850 | 260 |

Core Equipment

Applicable Materials