Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

Vertical Preheater

Specifications:

The vertical preheater is a vertical preheating device that preheat calcined material, It main used to preheat raw material with poor thermal stability (such as limestone, dolomite and so on).

Application Range:construction, building, metallurgy, mining, industrial garbage waste disposal,chemical and other relevant industries.

Applicable Materials:limestone ; dolomite

Superior design and resonable structure

Push head and main parts of body is made of heat resistance steel, so it can work in 1000~1100℃ high temperature, and have long operation life.

High thermal efficiency

Effectively recycle heating energy in waste gas from kiln inlet , to insure the material is preheated equally and reach to preheating temperature.

Clean working environment

Recycle the heat energy in waste air that discharge from kiln tail effective, increase utilization ratio of fuel, at the same time, it’s benefit to dedust;

Less occupation area

The vertical preheater is used in calcination system, the length of rotary kiln will be shorten, to reduce the heat loss on the surface of rotary kiln and floor space;

Bring customers with good profits

With good combined revenues, the capacity will be increased 30%, thermal efficiency will be increased 40% after use vertical preheater.

Working Principle

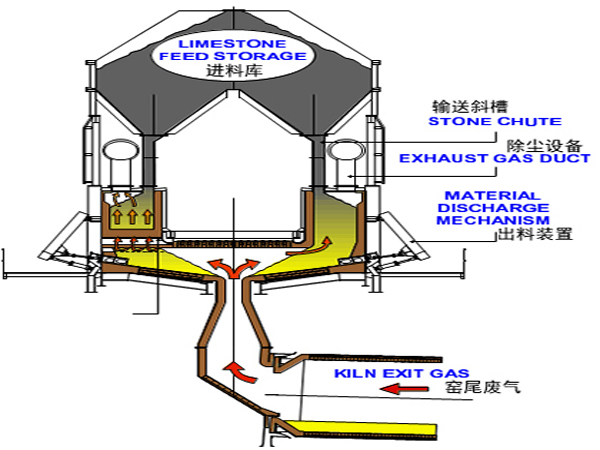

Vertical preheater is consist of upper feeding system, suspended ceiling device, main body, pusher system, hydraulic system and so on. Concrete structure such as below drawing. The characteristics of each sub-system is:

1. Upper feeding system

It main include upper hopper, discharge chute, hopper legs and so on, its main role is to ensure complete sealing when feeding materials into main body of preheater, and avoid cool air enter into preheater.

2. Suspended ceiling device

Its main role is bearing the weight of hanger bricks.

3. Main body of preheater

The main body of preheater is consist of preheating room, hanger device and so on, it’s the key part of ensuring materials preheated more than 800℃。

4. Pusher system

Include push head, liner support frame and so on, to ensure push materials steady, reliable and accurate.

5. Hydraulic system

Include oil box, oil pump, motor, electro magnetic valve, hydraulic oil tube and so on, it’s main used to control pusher device, complete push action.

6. Bottom feed hopper

Include feed hopper and so on, its main used to import preheated materials into rotary kiln by transfer chute for calcination.

7. Recycle system

Include dust collection silo, recycle slide pipe and so on.

Latest Delivery

Project Case

Jinan 350TPD Lime Kiln Production Line

Attracted by lime rotary kiln manufactured by china famous rotary kiln supplier, Zhengzhou Taida, Jinan customer purchased a whole set of lime rotary kiln calcining machine to fulfill final production aim. The picture shown above presents the real working condition of Taida lime rotary kiln.

Raw material: Lime

Output capacity:350T/D

10TPH Russia Gypsum Production Site

Gypsum with high moisture is sent to hopper. Then, gypsum will enter the feeding end of rotary kiln dryer. Under this situation, the inclination of feeding end will be larger than natural inclination of gypsum.then, gypsum will enter rotary kiln dryer smoothly. calcining rotary kiln is a rotary drum with certain inclination.

Raw material:Phosphaste gypsum

Output capacity:1-10T/H

Technical Parameters

| Model |

Output (t/d) |

Power (kw) |

Thrust device |

| TDYR-2-6 |

200 |

18.5 |

heat-resistant steel |

|

TDYR-3-8 |

300 |

18.5 |

|

|

TDYR-4-8 |

400 |

22 |

|

|

TDYR-5-12 |

500 |

25 |

|

|

TDYR-6-12 |

600 |

25 |

|

|

TDYR-8-18 |

800 |

34 |

|

|

TDYR-10-22 |

1000 |

45 |

Core Equipment

Applicable Materials