Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

Cement Mill

Specifications:

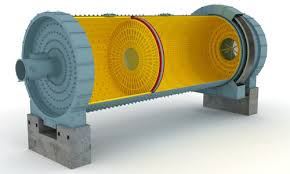

mainly consists of cylinder, lining plate, shifting board, main bearing, feeding and discharging device and driving device.

Application Range:cement, steel slag, limestone, limestone, gold, gold ore, coal mud, mineral powder, slag and other materials.

Applicable Materials:mainly used in grinding of cement finished product and materials, also to the metallurgical, chemical, electricity and other industries.

|

Simple structure, stable operation |

Engergy saving |

Large output capacity |

Long service life |

|

|

|

|

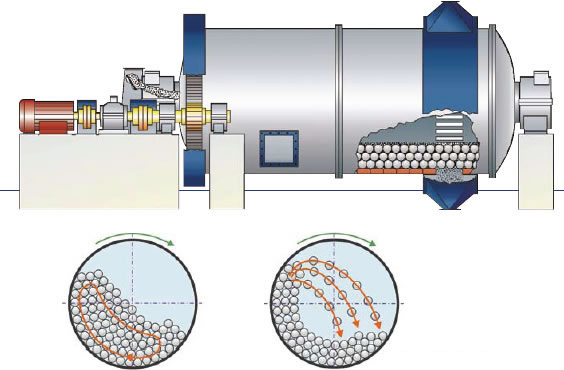

Working Principle

|

|

Cement ball mill is mainly consisting of feeding device, big gear, discharge device, cylinder, diaphragm plate, hollow shaft, liner, drive device and other components.

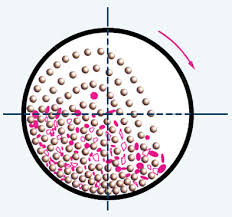

When mill cylinder is driven to rotate by the transmission device, the abrasive body is attached to the lining surface of the inner wall of the mill cylinder due to the action of inertial centrifugal force, and is rotated to a certain height, and then freely falls by gravity. At this time, the grinding body crushes the material in the cylinder, and at the same time, the grinding body has a rising and falling circular motion in the rotating mill, causing sliding and rolling, causing grinding between the grinding body, the lining plate and the material to be ground to make the material Grinding.

|

Latest Delivery

Project Case

500TPH Mongalia Ball Mill Line

Customer is from a molybdenite mine. Non-iron ore contains much silica contents. Owing to large-scale exploration recently, ore features has changed a lot. After times discussion of Taida engineer, we put forward a set of high-output ball mill grinding line for customer.

Material:copper ore,<800mm

Capacity:500t/h

Philipines Granite Crushing Line

This customer is from mining group in Manila, Philippines. This company holds strong running experience. They mainly ordered machines like PE750*1060, PF1315 impact crusher and PE1010 impact crusher.

Material:granite,<800mm

Output size:<30mm

Capacity:200t/h

Technical Parameters

| Specifications(m) | Type | Transmission mode | Reducer | Motor power(kw) | Capacity (t/h) | Weight(t) | |

| Model | Speed ratio | ||||||

| φ1.5×5.7 | Open-flow | Margin | ZD40 | 3.55 | 130 | 4.5-6 | 25.8 |

| φ1.83×6.4 | Open-flow | Margin | ZD60 | 4.5 | 210 | 7.5-15 | 43 |

| φ2.2×6.5 | Circle-flow | Margin | ZD70 | 5 | 380 | 14-26 | 60 |

| φ2.4×7 |

Circle-flow

|

Margin | ZD70 | 5 | 475 | 24-28 | 81 |

| φ2.4×10 | Circle-flow | Margin | ZD80-4-Ⅱ | 6.435 | 570 | 32-36 | 118 |

| φ2.6×10 | Circle-flow | Margin | JDX710 | 6.3 | 800 | 45-50 | 130 |

| φ3×9 | Open-flow | Margin | JDX800 | 6.3 | 1000 | 55-60 | 158 |

| φ3.2×9 | Circle-flow | Margin | MBY900 | 7.1 | 1250 | 62-65 | 195 |

| φ3.5×10 | Open-flow | Margin | JDX900 | 5.84 | 1250 | 70-75 | 200 |

| φ3.8×7.5 | Circle-flow | Margin | JDX900 | 5.6 | 1600 | 80 | 233 |

| φ4.6×10+3.5 | Circle-flow | Center | JQS3550 | 15.1 | 3550 | 190 | 415 |

| φ4.6×10.5+3.5 | Circle-flow | Center | JQS3550 | 15.1 | 3550 | 210 | 476 |

Core Equipment

Applicable Materials