Zhengzhou Taida welcome your visiting to our website!

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

SITEMAP|

中文站|

CONTACT US|

ONLINE MESSAGE

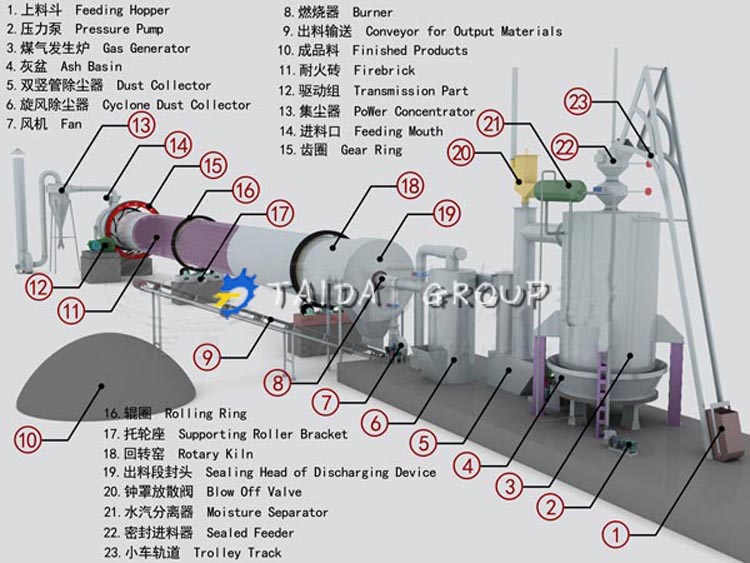

Gas Burning Lime Kiln

Specifications:

Gas burning lime rotary kiln is a kind of new emerging lime production technology. It is well known that lime is made from limestone. The main ingredients of limestone is CaCO3. After calcining, lime will become calcium oxide. Limestone can be decomposed into lime as long as a certain amount heat is provided.

Application Range:Building material, metallurgy, chemical industry, electrical power and etc.

Applicable Materials:cement, Lime,Refractories, Metakaolin, Titanium dioxide, Alumina, Vermiculite, Iron ore pellets.

1. Advanced burning mechanism and less heat loss

It adopts fully sealed calcining mechanism. Multi-layer refractory materials are adopted in internal kiln. The design lifespan is more than 5 years. Meanwhile, in order to use energy effectively, heat exchange is adopted by upper and lower kiln part, which mostly reduces thermal loss.

2. Advanced technology, high efficiency and good quality of lime

The machine designed by our company uses vertical preheater with advanced structure and lower pressure loss. These advantages can not only improve production efficiency. In addition, lime produced by this machine holds good quality and high activities. It is a kind of ideal energy-saving lime kiln equipment.

3. Advanced structure and high investment profits

The rotary kiln structure should be made according to flame length and output capacity. It is testified by practice that gas burning lime rotary kiln should be bigger instead of smaller. One should make sure good air permeability. In fact, the distributing device is simpler than that of coal kiln. The proportion of fuel gas and air is supposed to be rational. The working principle of this machine is very easy.

Working Principle

Latest Delivery

Project Case

Jinan 350TPD Lime Kiln Production Line

Attracted by lime rotary kiln manufactured by china famous rotary kiln supplier, Zhengzhou Taida, Jinan customer purchased a whole set of lime rotary kiln calcining machine to fulfill final production aim. The picture shown above presents the real working condition of Taida lime rotary kiln.

Raw material: Lime

Output capacity:350T/D

10TPH Russia Gypsum Production Site

Gypsum with high moisture is sent to hopper. Then, gypsum will enter the feeding end of rotary kiln dryer. Under this situation, the inclination of feeding end will be larger than natural inclination of gypsum.then, gypsum will enter rotary kiln dryer smoothly. calcining rotary kiln is a rotary drum with certain inclination.

Raw material:Phosphaste gypsum

Output capacity:1-10T/H

Technical Parameters

|

Specifications (m) |

Dimension | Power (kw) | Total weight (t) | Notes | ||||

| Diameter (m) | Length (m) | Inclination (%) | Output (t/h) | Rotary speed (r/min) | ||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | With vertical preheater |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ---- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196.29 | ---- |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ---- |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201.58 | Decomposition outside the kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ---- |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | Decomposition outside the kiln |

| Φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 | Bauxite calcining kiln |

| Φ3.2×50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | Decomposition outside the kiln |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | preheat decomposition |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | preheat decomposition |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Residual heat power |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | preheat decomposition |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | preheat decomposition |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 | preheat decomposition |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | preheat decomposition |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | preheat decomposition |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | preheat decomposition |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | preheat decomposition |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | preheat decomposition |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | preheat decomposition |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | preheat decomposition |

Core Equipment

Applicable Materials